고정 헤더 영역

상세 컨텐츠

본문

Jun 4, 2015 - As Amazon's #1 best seller in cutting boards, the CounterArt Flexible Cutting Mat is an affordable set of brightly colored cutting mats (11.5' x.

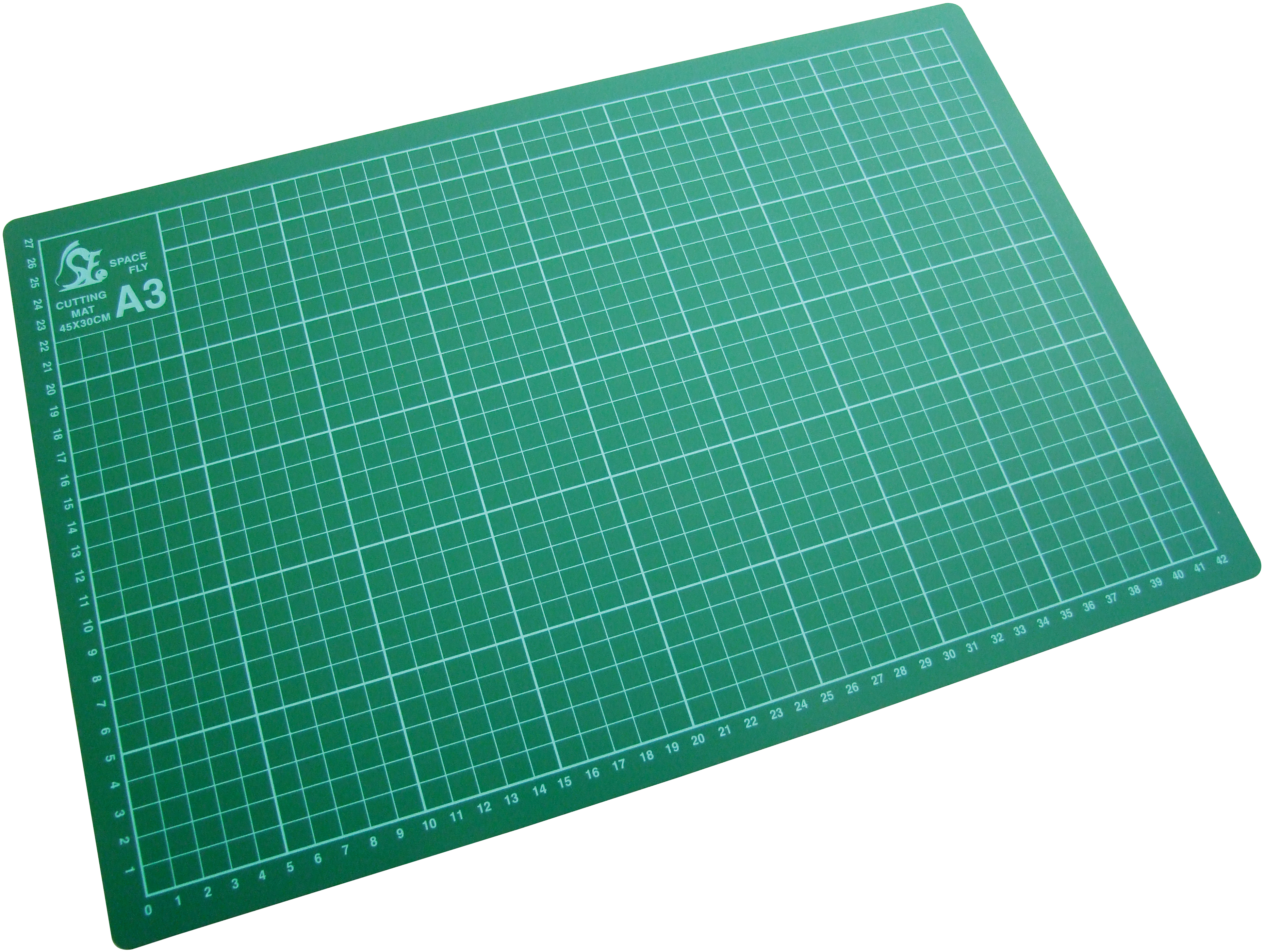

Self healing cutting mats by Alvin and Magic Mats are made from a unique composite PVC vinyl material with sold plastic core. Multi-ply rotary cutting mat provides a long-lasting surface that can be cut without showing marks or cutting lines. Perfect for signmakers, framers, printers, photographers, graphic artists, designers, quilting, sewing, scrapbooking, fabrics, industrial applications, and more.

Each self-healing cutting mat features:. Self-healing, reversible, non-glare surface is almost twice as thick (approx. 3mm) as most 'hobby' mats. Designed for both rotary and utility knives; keep your blades sharper longer. Printed square grid pattern includes angled guide lines. All four edges are fully numbered and graduated with hash marks extending beyond the zero base line for convenience.

Custom Cut Mat Board

Non-stick surface is impervious to abrasions and liquid spills. Easy to clean and maintainDISPLAYED BY SIZE BELOW (LARGEST TO SMALLEST). SCROLL TO BOTTOM OF PAGE FOR MORE INFO!

Self-Healing Cutting Mat Comparison: Alvin vs Magic Cutting MatsAlvin self-healing cutting mats are one of the best-reviewed mats on the Internet. They are similar in construction to the green Magic Mats. Alvin professional cutting mats are available in larger sizes-up to 4 ft.

Both have multi-layer construction with colored vinyl outer layers and an inner layer of hard plastic. Alvin green and black mats are reversible with grids on both sides. The translucent mats are gridded on one side only as are the Magic Mats. Magic Mats can be custom-cut; Alvin cannot.

Both self healing mats are superior in quality and construction to Omnigrid and OLFA mats. Great rotary cutting mats for quilting, sewing, fabrics, and more. All are professional-quality and will help you complete most any cutting project.

Best Sellers.#1: Always popular, the John Boos R02 reversible maple cutting board. Extra large with 24' x 18' surface.#2: Awarded 'Best Cutting Board' by America's test kitchen, the Proteak Model 107 teak cutting board.#3: Beautiful acacia wood, with the look of walnut but only 1/3rd the price.#4: John Boos end grain butcher block with American maple.#5: For the knife afficionado, hinoki is regarded as the best wood to use for cutting. Exclusively imported by CuttingBoard.com.#6: Exquisite American Black Walnut made by John Boos, the most famous name in cutting boards and butcher blocks.#7: Premium 2-1/4' thick American Maple with side handles.

Also by John Boos.#8: Our exclusive all-in-one cutting board maintenance kit, with mineral oil, wood wax and applicator cloth.#9: John Boos Mystery Oil, made for butcher blocks, countertops and cutting boards.#10: Bartow Board Tonic, a plant based wood oil that is food safe, non-toxic and vegan friendly. Great for salad bowls and utensils. At CuttingBoard.com, we often get questions along the lines of,'What is the difference between a butcher block and a cutting board?' As well as the more interesting, 'Can I use my cutting board to chop meat?' Both are very good questions, as they are two very distinct surfaces for different purposes.For a little bit of history, the use of a butcher block first originated in China, though Europeans have used butcher blocks for centuries as well. The concept was to have a sturdy base on which to butcher meat, hence, the 'butcher block'.

The physical act of chopping is also why these blocks are also commonly called chopping block as well.In the past, just about anything could pass for a block, be it a tree stump, log round or even a flat rock (though we imagine that idea didn't last long due to the damage to the knives). These days, butcher blocks are be described as anything from a round 5' wood board to a stand alone table to a 20 square foot kitchen island. No wonder there's some confusion as to the technical definition of a butcher block, because the reality is that the definition is in the eye of the beholder and you can see ourin varying shapes and sizes.A Butcher Block is Defined by the Role in the KitchenIn food preparation, knives are the ultimate chef's tool and go hand in hand with your prep surface. Prepping of vegetables normally involves knife work such as slicing, chiffonade, julienning, dicing and chopping. This is where your standard cutting board does the job, as all boards can handle light prep work.Meats on the other hand, require quartering, deboning, chopping and filleting, which require a larger working surface that is also sturdy enough to stay in place and not be damaged.

Most of the butcher blocks you see here on CuttingBoard.com areat least one and a half inches thick and are assembled using end grain. Thickness is important because it adds the most important factor: weight.We often see one inch boards that are marketed as butcher blocks, but if you're quartering meat, the last thing you want to do is worry about the block sliding away and having your meat go airborne or onto the ground. This is also the reason we generally recommend rubber feet for smaller boards or putting a kitchen towel under the block so it doesn't slip. With bigger, heavier butcher blocks or cutting boards, it's not so much an issue.Grain edge is the other tell-tale sign of the role of a butcher block. In our opinion, all butcher blocks should be made with end grain as opposed to edge grain. End grain means that the end of the wood fibers are exposed, whereas edge grain means that the grain is running along the outside. The major difference is that end grain is resistant to cuts and scarring and is evenself-healing over time, as the density of the fibers will push back into place.

This is why there are even some softwoods that are used for making butcher blocks, as the benefit of end grain surpasses the benefits of using a hardwood with edge grain.So, according to us, a butcher block must meet our three rules:. Made using end grain. At least 1.5' inches thick.

Large enough to adequately handle the meat you butcher (we say a minimum 12' x 12' surface)Can Cutting Boards Be Used as Butcher Blocks?This question is much easier to answer now that we've established our three rules. If your cutting board matches the definition above, then you should have no qualms using it as a butcher block (or chopping block).Of course, like many things, our definition isn't an exact science and if you're careful, you can probably get away with quartering your meat of choice on small plastic cutting board; just don't call it a butcher block. That said, if you do have a wood cutting board that is less than one inch thick and are doing some serious butchering, don't be surprised if you see cracks forming over time.

If there's anything we hate seeing, it's a nice beautiful board with a crack down the middle, so we always recommend a true butcher block for a serious chef.A popular seller is this. At 3' and made with end grain American maple, it is made for the serious chef. Or if you're looking for a budget block, this similarly sized is a good value for the price.